Sustainability is the ultimate driver for innovation in the chemical industry. As the earth continues to experience an environmental crisis whose deadline for solutions was yesterday, the industry must make sustainability happen today through circularity, innovation and collaboration. Consequently, one of the leading chemical players, Clariant, is making decisive moves to push the sustainable development goals 12 and 13: responsible production and consumption, and climate change respectively.

Dr Martin Vollmer, Chief Technology Officer at Clariant, shared some of the key initiatives through which the company is innovating sustainability at the 2021 CIEX conference. Clariant’s activities span three core areas: care chemicals, catalysis and natural resources. In order to achieve truly transformative goals in these areas, sustainability has been embedded in the company’s values and strategy. This strategy is five-fold:

- Focus on innovation research and development

- Add value with sustainability

- Repositioning of its portfolio

- Intensified growth

- Increased profitability

However, the validity of any strategy is underlined by its execution. For Clariant, innovating towards greater sustainability in the chemical industry meant tackling seven sustainability challenges in five ways.

Seven Sustainability Challenges of the Chemical Industry

While these challenges are clear and distinct, Dr Vollmer emphasizes that they are connected through their solutions.

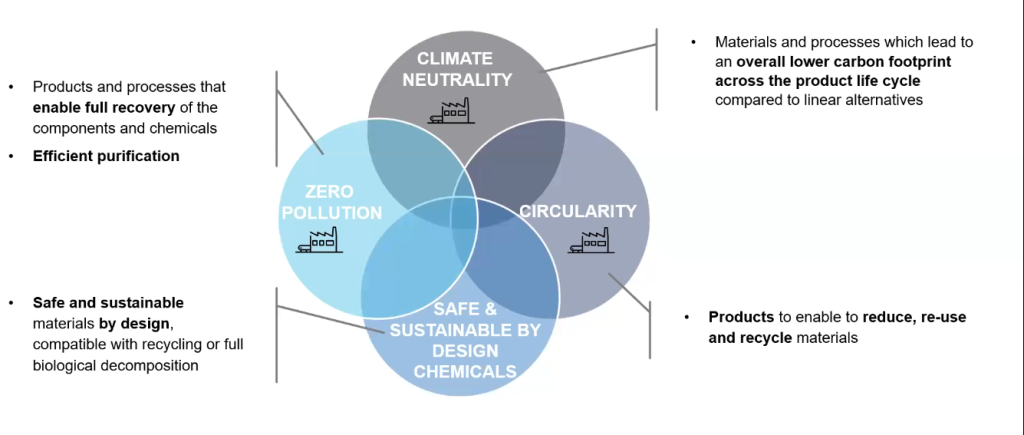

In this vein, a special department at Clariant called Sustainability Development Unit is responsible for collaborating with other departments in order to unite efforts towards climate neutral operations and a sustainability driven portfolio change. So how does Clariant work towards goals while addressing these seven challenges?

1. Setting Clear Measurable Goals:

Following from the broad goal of zero net emissions, Clariant decided to establish ambitious interim goals towards 2030. To improve the climate change crises by reducing greenhouse emissions by a combined 54%. On the other hand, making operations more sustainable by decreasing water intake and waste by a combined 45%, reducing landfilled non-hazardous waste by 40% and hazardous waste by 45% among others. The sustainability unit consistently monitors relevant data on these goals to improve solutions.

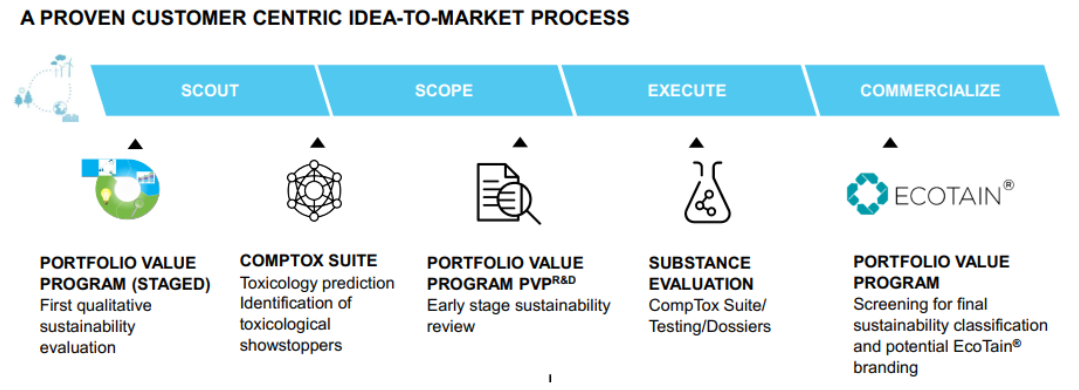

2. Consumer-Centric Innovation Process:

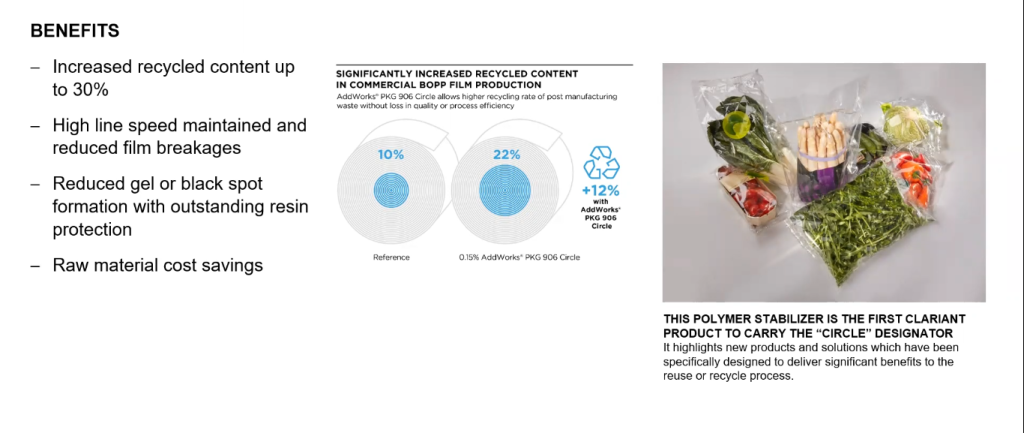

Consumers are increasingly concerned about the carbon footprint of the products they purchase. Thus, adapting the product innovation process for circularity is a big deal at Clariant. Using industry generated tools like CompTox Suite, the company is able to evaluate innovations at the very earliest stages. Dr Vollmer encouraged the use of CompTox Suite for instance, because of its ability to highlight elements that may seem neutral at first but prove hazardous eventually. When everything goes well, a product typically hits the market with the EcoTain certification – a mark of sustainability.

3. Biomass feedstock:

By 2050, it is predicted that fossil feedstock will be totally eclipsed in the chemical industry by bio-based, CO2-based and recycled feedstock. Clariant has chosen to take an active part in this eradication of fossil feedstock and effectively make sustainability happen by engaging in circular solutions, hydrogen economy and bioeconomy. This is where most of the magic happens, and partnership is key.

Increasing ROI from Biomass Feedstock

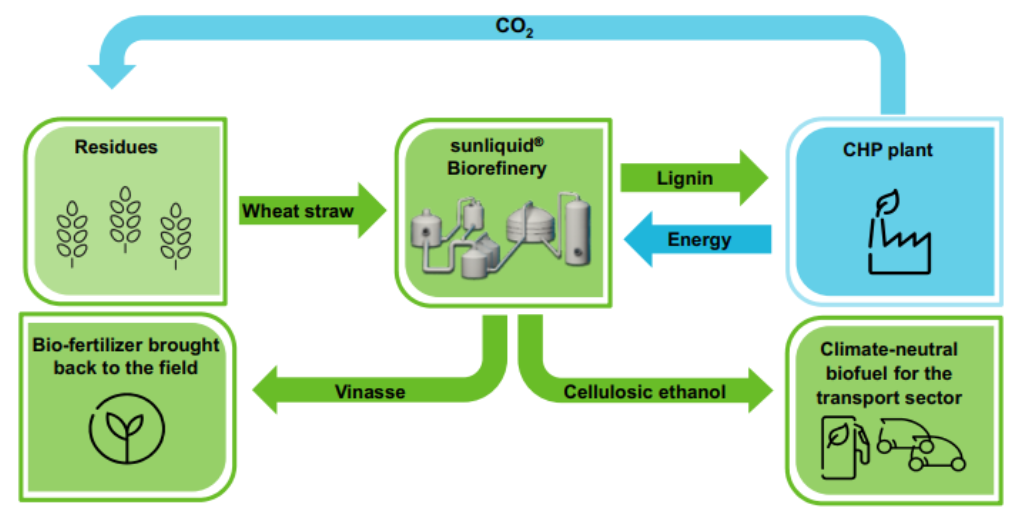

The sunliquid process takes the enormous waste from agricultural products. For example, wheat stalk and processes them into cellulosic sugar and eventually cellulosic ethanol. Dr Vollmer puts the massive environmental savings into perspective by illustrating that from the hectre which produces seven tons of crop also comes up to five tons of straw. The seven tons goes into production of starch sugar for nutrition but what happens to the five tons of straw? Often they are burnt.

However, those five tons have the potential to yield up to 2.5 tons of cellulosic sugar! And this without interfering with the food chain. The need to profitably access this yield and transform it to ethanol inspired sunliquid® technology. This technology is the chief Clariant product not the second generation bioethanol; this is because wide-adaptation of the technology can bring significant changes. Also, beyond bioethanol, the sunliquid® process has the capacity to generate other biochemicals through biotechnology and catalysis.

Pilot Plant in Romania Shows High Energy Savings

To illustrate the commercial viability of this technology, Clariant is setting up a plant in Romania to prove their concept to stakeholders. When implemented correctly, sunliquid® plants will achieve high energy savings. It reduces greenhouse gas emissions by up to 120% (taking carbon capture into consideration) and save up to 147,000 tons of carbon dioxide emissions in the transport industry with just one plant.

The goal with Clariant’s first plant in Romania is to valorise 250,000 tons of straw to produce 50,000 tons of bioethanol per year. Like its products, the plant is poised for circularity in the way it effectively engages the by-products of operations. Two key byproducts of the process, lignin and vinasse are fed back into the system. Lignin is used as an energy source to power the sunliquid® plant, and vinasse as a bio-fertilizer for the wheat fields.

In order to make the plant completely circular there is an opportunity for partnerships in capturing CO2 emissions. At the same time, feeding it back into the system as residue to be re-processed.

Safe and Sustainable Design Outside the Plant

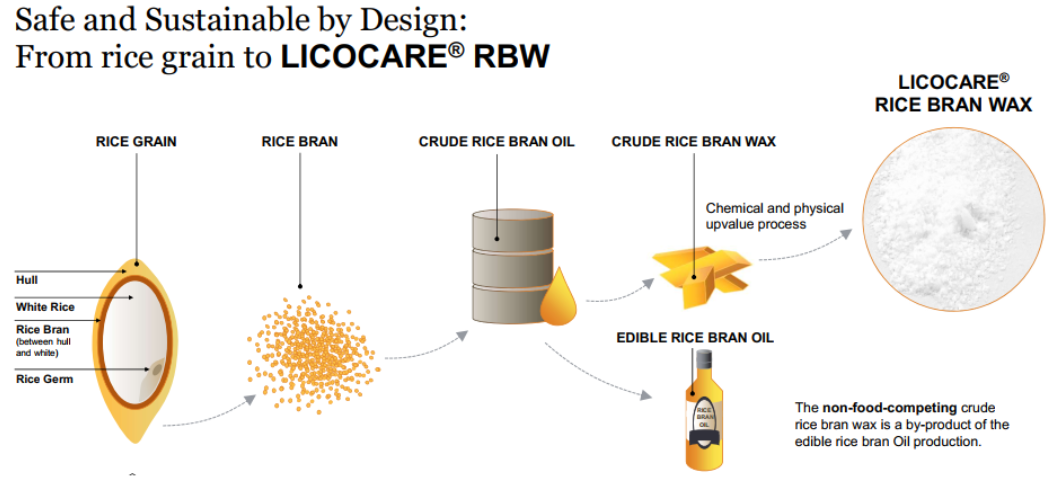

To improve sustainability in the chemical industry, stakeholders must continually question how they can make even the extraction process of nutritional elements more circular. One example Dr Vollmer uses to illustrate the economic potential here is Clariant’s Licocare® from Rice Bran.

The difference between edible rice bran oil and crude rice bran oil is mostly the crude rice oil wax. This wax is a byproduct of the process and often ends up as waste. In line with their goal of reducing waste by 45%, Clariant upvalues this wax to produce Licocare® Rice Bran Wax, a bio-additive solution for plastics. Additionally, this meets the needs of Clariant’s plastic customers, making it a win-win in people, planet and profit.

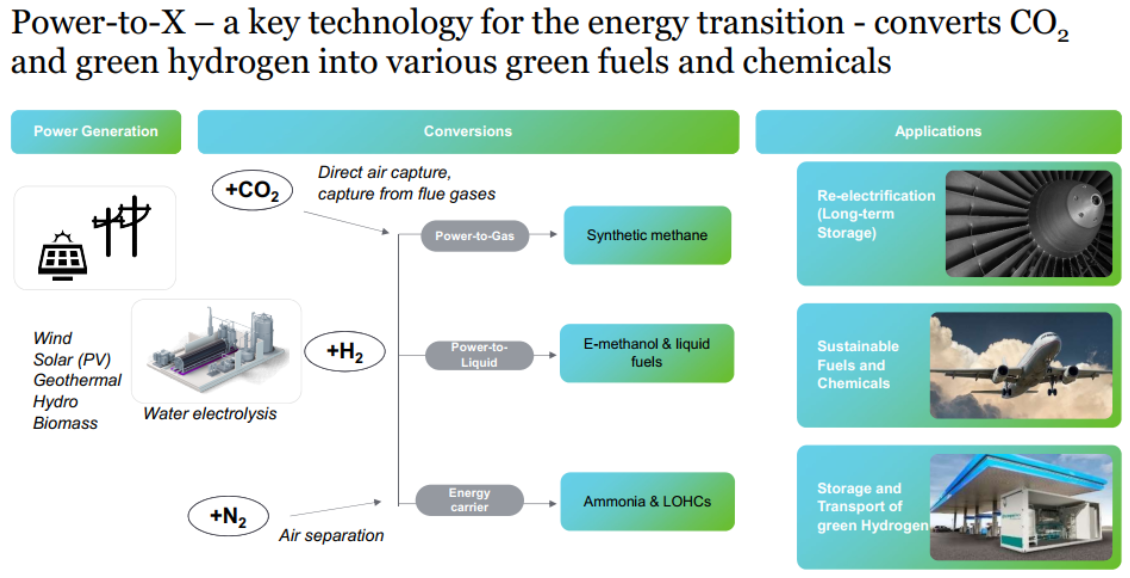

- CO2 as Feedstock: Here, Clariant enters the Hydrogen economy. The goal is to hydrogenate CO2 to produce methane, ethanol and possibly (depending on the availability of hydrogen), Ammonia – a new energy carrier. To this end, Clariant is working towards establishing plants to purify CO2 emissions from steel production. Why the steel industry? Because it accounts for 5% of global emissions.

- Partnering for Circularity: Some goals may seem daunting even in the long term. There are several immediate ways in which stakeholders can contribute to innovation in the chemical industry for sustainability. Participating actively in policy development and sustainability discourse does go a long way in partnering for circularity. This is why Clariant sits on the table of various global organisations like the World Economic Forum’s Low Emitting Technologies Initiative.

Nevertheless, Clariant is just one player. The potential for sustainability in the chemical industry depends on the willingness of all stakeholders to innovate towards it. The aim of sharing Clariant’s goals and methods is to provide content that can catalyse further innovation and partnership. Remember, the Earth’s crises needed a solution yesterday. So what will your company do today?

Your next chance to join CIEX live is CIEX 2022 in Frankfurt, October 5&6, 2022. Book your ticket at https://ciex-eu.org/.

In addition, you can find past presentations in our video archive at https://ciex-eu.org/presentations-from-ciex-2020/#

[adrotate group=”1″]

Find more related articles below:

Gaining competitive advantage with the circular economy

Bridging the gap between idea and industry – BASF Venture Capital

The road towards circularity and carbon neutrality at Braskem