Sustainability is the language of the future

Sustainability is the language of the future. So, if your business wants to gain a competitive advantage, it must enrol in the school of the circular economy. This was the key message of Richard Haldaimann’s presentation at CIEX 2020.

The circular economy stands on three principles: reduce, reuse, and recycle. The goal is to recreate the natural ‘circle of life’ in the industrial process.

Typically, what we have is a linear trajectory. From raw materials straight to final product, with humungous waste to show for it. This waste which is triggering scientific panic attacks whenever any discourse related to the environment comes up. So, the industrial process needs to change.

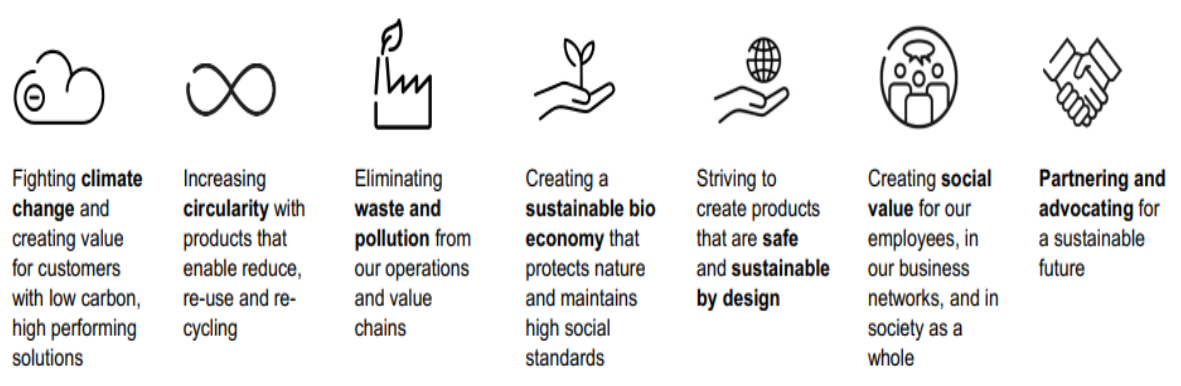

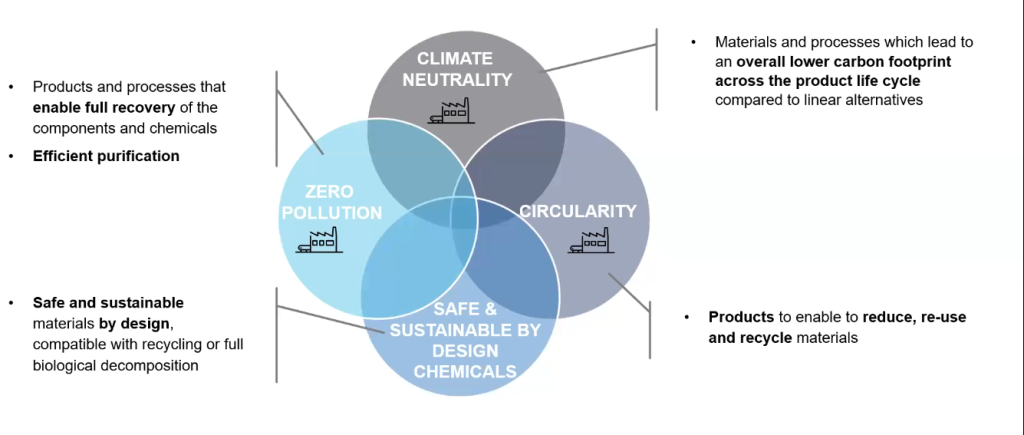

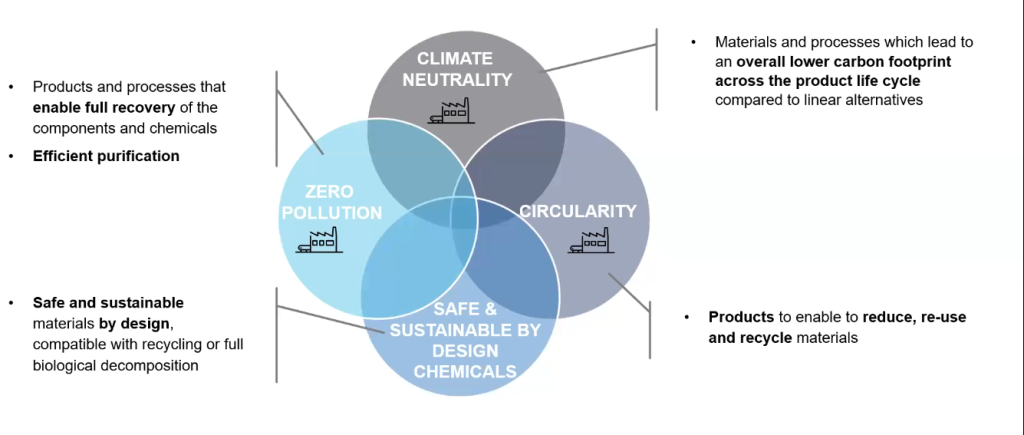

However, circularity is only one dimension of sustainability. It has to interact with others so that its purpose isn’t defeated.

Incorporating circularity implies a need to strive for climate neutrality by lowering the overall carbon footprint in a product’s lifecycle. After all, what’s the point of an easily recyclable product if you have to burn more carbon to get it? Reduce.

Figure 1: Dimensions of Sustainability

Circularity equally underscores the goal of zero pollution. This means working towards recovering components involved in production, allowing you to Reuse.

You also need to integrate safer chemicals into the production process. Fully biodegradable chemicals, and if not, at least make it easier to Recycle.

Keeping this picture in mind will help you smoothly implement Richard Haldaimann’s 3 steps to securing your competitive advantage. Richard is the Head of Sustainability Transformation at Clariant, an industry leader that provides over 9,000 speciality chemicals to a broad industry.

THREE STEPS TOWARDS A CIRCULAR ECONOMY

1) Make circularity and sustainability a strategic imperative

2) Provide your organization with the manpower and connections to access circular business opportunities

3) Foster value chain co-creation and easy-to-understand marketing communication.

ESTABLISH A STRATEGIC IMPERATIVE FOR CIRCULARITY

Naturally, nothing works till you decide it matters enough to work. Even from a utilitarian perspective, you can’t lose with the circular economy. By opting for a production cycle rather than a production line, you’ll be effectively:

– Reducing the cost of production due to increased recycling

– Abating consumer anxiety about pollution. Less anxiety improves brand love, thus, pushing competitive advantage.

– Cultivating positive relationships with environmentalist organizations as well as industry stakeholders.

As soon as you decide you have to, the foundation is already solid.

EMPOWER YOUR ORGANIZATION TO ACCESS CIRCULAR BUSINESS OPPORTUNITIES

Now for the pillars. Obviously, how to do the deed is unique for each organization, but the principles remain the same.

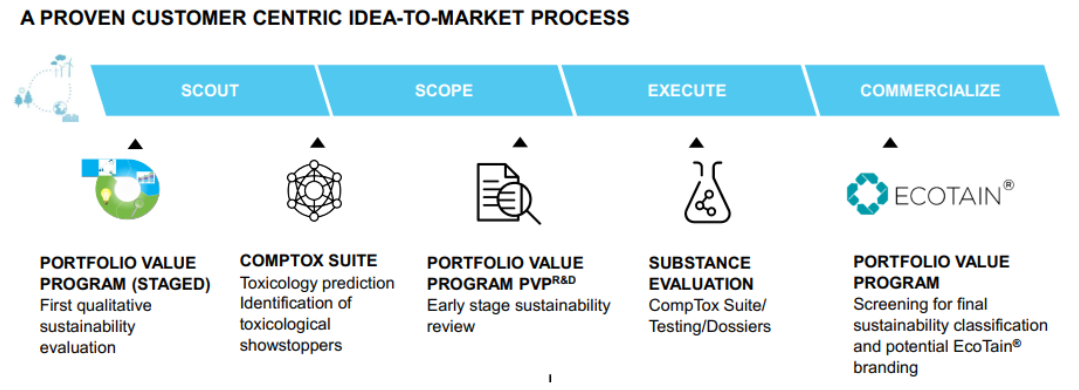

1) Hardwire sustainability into your production process

At every step of the way you have to investigate how to bring in the dimensions of circularity.

Like this, you’re not trying to find a way to ‘fit’ your product into the circular economy, rather you’re ENGINEERING a product for the circular economy. Beginning at ideation, conduct market research that highlights the sustainability needs and concerns of your customers.

This ensures the development of a product that wasn’t just sustainable on your end but improves the sustainability of other products it interacts with along the value chain.

Regarding Clariant, this approach involves conducting a customer survey on the toxicology and recyclability of their chemicals; including their effect on the customer’s manufacturing process.

2) Create a Team

You need a team of dedicated professionals that combine strategic leadership with excellent capabilities to yield sustainability transformation. Here’s the organizational structure Clariant implements.

– Advocacy and Public affairs: This department is all about cooperating with legal stakeholders, and providing insights on policy developments.

– Sustainability affairs: Your opportunity trackers. They are responsible for bringing all stakeholders to the table and engaging them to discover what issues need to be addressed. An efficient research and dialogue team.

– Sustainable portfolio: Your innovation experts. They mastermind solutions. Providing answers which adapt research findings.

– Sustainable Operations: Finally, your engineers for turning those ideas into reality.

Figure 2: Leadership and Responsibility

3. Cross Business Unit Platform

Richard says “collaboration manages complexity and achieves circular economy solutions”. Accordingly, you have to create some kind of platform that encourages cooperation towards sustainable innovation among members of a value chain.

For the plastic industry they cater to, Clariant developed Ecocycle. An entity that unites business units such as recyclers, polymer producers, etc to collectively achieve the goal of reducing plastic waste.

MARKETING COMMUNICATION AND VALUE CHAIN CO-CREATION

What good is all that hard work if it isn’t adopted? For Richard and his team, the first way to eliminate this hurdle is through value chain co-creation and designing for marketing communication. Here’s a good example of how this worked in Clariant.

Value Chain Co-Creation

In the body care industry they cater to, there’s a widespread use of black plastic packaging to create a sense of product exclusivity. Sadly, the dye for these plastics isn’t compatible with the sorting process involved in recycling (sustainability affairs).

So, Clariant involved a key manufacturer in the body care industry-Unilever, and the manufacturers of these sorting machines-Tomra, in generating a solution.

The task was to solve this problem while satisfying the marketing strategy of the black aesthetic (sustainable portfolio). In the end, they created a black (sustainable operations) Near-Infrared (NIR) detectable colourant that met this need.

The market adoption was fantastic. It created a new circular value chain and gave Clariant a competitive advantage.

Marketing Communication

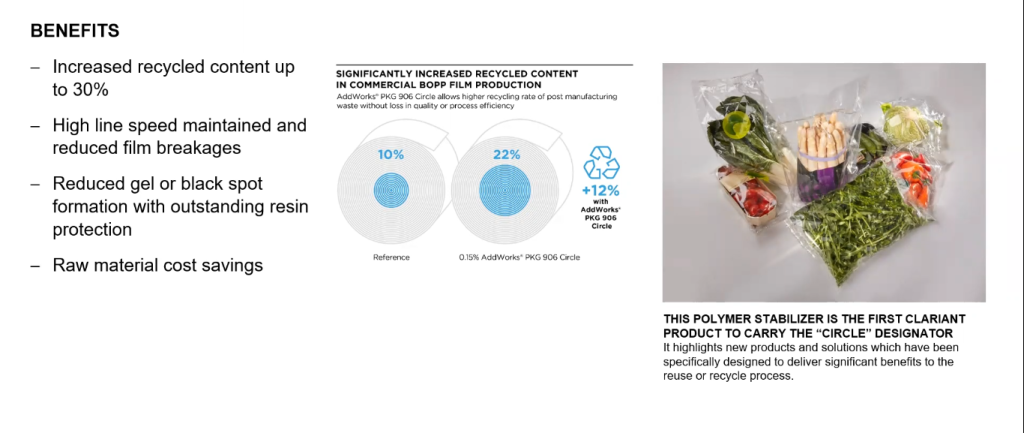

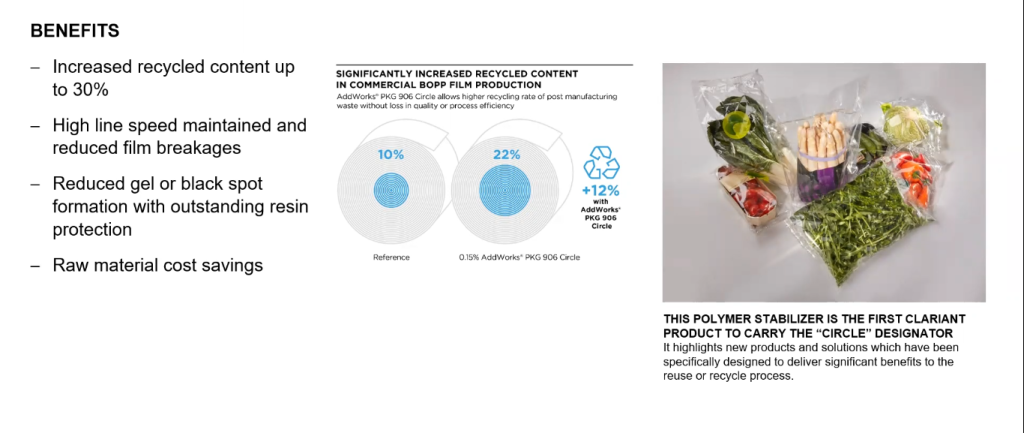

Marketing gives your product wings. To sell a product that provides circularity, you have to help marketing communication by creating a designator that points to that circularity. Hence, Clariant created AddWorks. Manufacturing guidelines that enable circularity. Addworks has a circle designator, printed on products that meet these criteria–a clear and easily understood distinction.

For example, Clariant created a polymer stabilizer which when used in the production of BOPP film, increases its ability to be recycled without compromising quality (more benefits below). The final product bears the designator. Thus, effectively communicating its circular value and encouraging adoption.

Figure 3: Benefits

Consider now the time to optimise your business for the reality of today. Innovate for the common good and earn your competitive advantage.

[adrotate group=”1″]

Your next chances to join CIEX live are during our CIEX Data Summit (Virtual conference, May 10, 2022)and CIEX Chemical Innovation Exchange (Frankfurt, October 5&6, 2022). Book your ticket at https://ciex-eu.org/.

In addition, you can find past presentations in our video archive at https://ciex-eu.org/presentations-from-ciex-2020/#

You might also be interested in:

Innovation is about the ability to spot opportunities and take advantage of them

An Interview with Dr. Martin Vollmer, CTO at Clariant

CIEX 2020: Pre-Conference Interview with Richard Haldimann, Head of Sustainability for Clariant

CIEX: Without giving too much away – what is the core message of your talk and what would you like delegates to remember?

CIEX: Without giving too much away – what is the core message of your talk and what would you like delegates to remember? CIEX: When looking to other regional markets, what lessons can the European chemical industry learn, adapt or perhaps even use to differentiate itself?

CIEX: When looking to other regional markets, what lessons can the European chemical industry learn, adapt or perhaps even use to differentiate itself?